Centralized Management Success with MIS System PiCSYS

Marushin Co., Ltd.

Mr. Kotaro Hiraki, Director and Factory Manager (right)

Mr. Ogata, Factory Manager, Offset Printing (left)

Marushin Co., Ltd. was the first company to establish an integrated production line for stickers, label printing, paper container printing, and promotional tool for the sale of these products. Having celebrated its 50th anniversary in 2017, Marushin is a one-stop total packaging company which boasts one of the largest production volumes in all of west Japan.

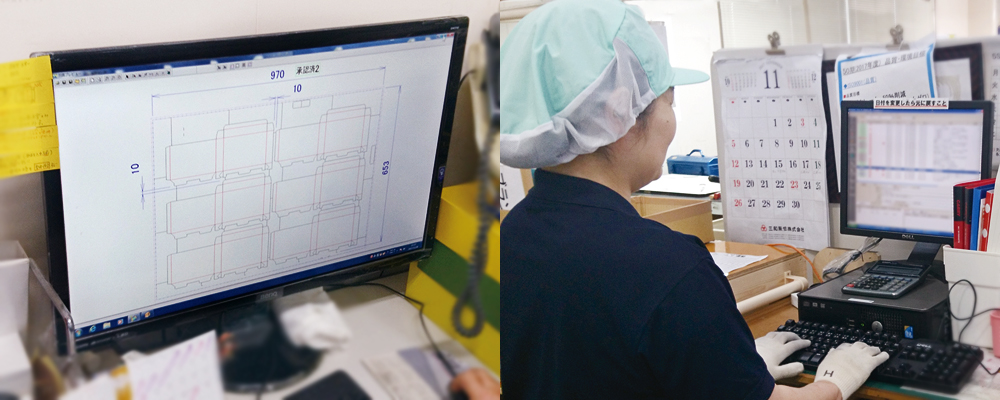

Unification of factory management has progressed rapidly with the introduction of PiCSYS, an IMS system for printing paper containers.

What are your strengths in the packaging industry?

solutions, from labels to

packaging and materials.

Mr. Hiraki: "Our company is deeply involved in materials, packaging, stickers, and labels, mainly for food companies. We purchase and sell packaging materials while manufacturing and selling labels. Among these, our strength is our integrated production. We have designers and photographers in-house, and we make our die plates and even the occasional sample at our factory. Many companies that handle paper packaging outsource their labels, but since we handle both in house, our associates can propose both to customers as a full set with packaging, labels, and materials. Also, there are many direct projects and promotional items, so if the customer's sales increase, we can make our own products. It is this strength that leads to additional sales."

What is your goal with introducing PiCSYS to your workflow?

Mr. Hiraki: "At our company, we have staff that handle quotations, planning, and schedules in the factory, but four of these six staff were due to retire at the same time. Each person had their own way of doing things as well, so if one person was out of the office, no one could cover for them. It was at this time in 2006 when I went to the Tokyo Pack trade show to find game-changing software to unify our workflow, and this is where I found PiCSYS by NSK. Many of the other solutions put out manufacturing costs such as quantity changes, but PiCSYS could handle a wide range of variables such as process and schedule management. I felt that PiCSYS had outstanding functionality, so I submitted a report about it to the company."

What circumstances led to the introduction of PiCSYS?

is unified and information

sharing is smooth.

Mr. Hiraki: "We decided to introduce PiCSYS in the year when one of our staff retired. Since we needed to hire new personnel at the time, we wanted to unify the workflow and make quotation preparation the same for everyone. One of the reasons for introduction was that I wanted to build a unified process. Until now, the methods of work were different for each associate, but after introducing PiCSYS, a method for sales to convey the content of the process to the company was established. For repeat projects, the past quotation history can be used, and now a system is in place so that even part-time workers can create a quotation on the sales team's behalf."

How did you handle production management before introducing PiCSYS?

Mr. Hiraki: "Each employee used Excel for paper packaging instead of production control software. Because there was no connection between staff workflows, many parts of the process relied on handwritten notes for ordering base paper. I calculated the cost with software I created myself, and entered it in the cost column of our in-house system."

"When PiCSYS was introduced, there were many long-time employees, so I planned to use it in parallel with the previous software. It was necessary to move only certain parts to PiCSYS first, and some estimates were operated in the old solution. However, due to the ease of use, I decided to take the plunge and completely do away with the previous software as well. I moved all members of management to PiCSYS, and migration did not even take a month."

What are your thoughts on PiCSYS?

a counter plate machine,

which is now in operation.

Mr. Hiraki: "The best part compared to other solutions is that there are many parts we can customize ourselves. So far, we have asked software makers to make minor specification changes to suit our business. However, each change we needed costed time and money. In that respect, PiCSYS has a very high degree of freedom."

Mr. Ogata: "I think it is great that recovery is easy even if something is input incorrectly. Even if you proceed with a mistake, you can start the project over immediately, so the burden on the operator is small. Also, the contact function for the next process is easy to use and is very convenient for urgent contact due to sudden changes in shipping dates or quantities."

What has been the largest benefit of the PiCSYS introduction?

means blanking forms or dies

are unnecessary.

Mr. Hiraki: "First of all, I wanted to be able to check the progress of each project in real time, even if I was away from my desk, and also to reduce the manual input of values and numbers in order to improve the productivity of each step. It can be solved in PiCSYS without relying on other software."

Mr. Ogata: "The largest benefit was that resistance to PC operation was reduced. Even people with no PC experience can operate PiCSYS effectively. I think that digitization has progressed very far in Japan. Another big advantage is that new information can be obtained in real time, even from other branches. In the past, information was not communicated because people did or did not hear the information. In PiCSYS, the data is saved at the time it was sent, and this data history can all be traced. I was able to easily judge whether or not I followed the confirmation rules, and matters of hearing or not hearing information decreased as time went on."

Solutions Introduced

PiCSYS: MIS System for the Packaging Industry

More Info PiCSYS is an integrated business management system created for the printing paper container, sticker label, and POP display industry.

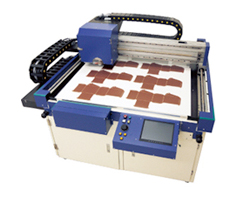

Crease-Line 8-ATC:

Counter Plate Manufacturing

More Info A dedicated machine for Counter Plate processing. The 8-ATC is equipped with an Automatic Tool Changer for speed and safety.