Event Report - TOKYO PACK 2016

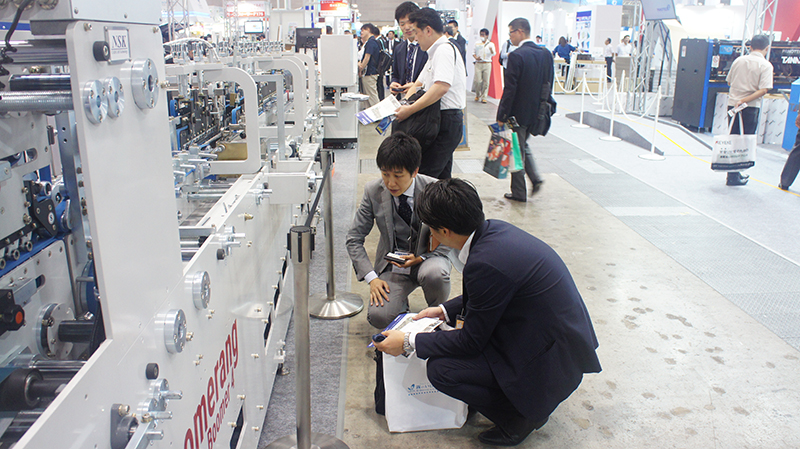

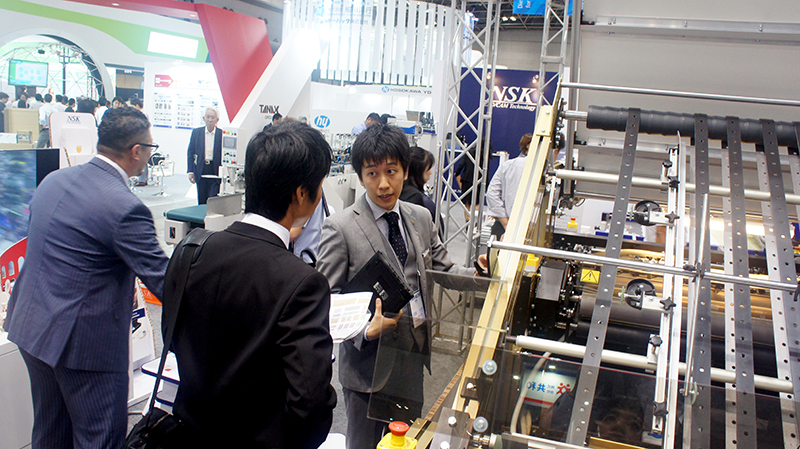

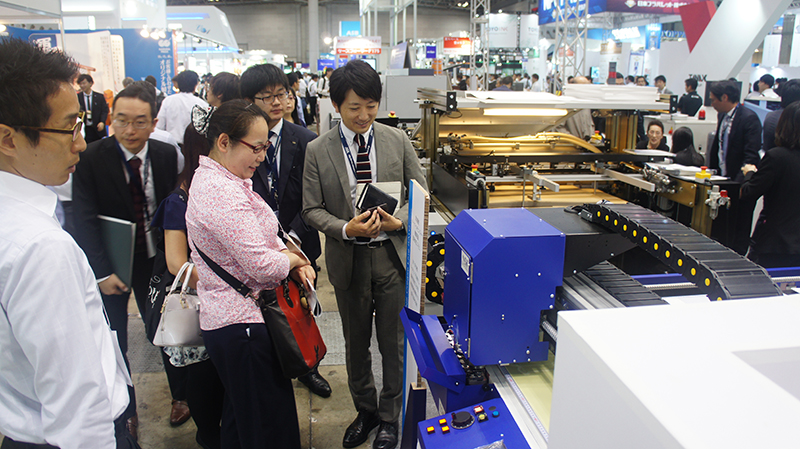

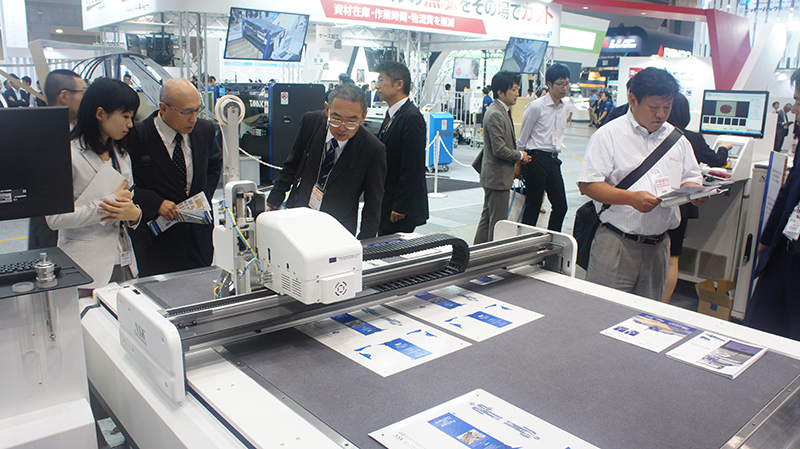

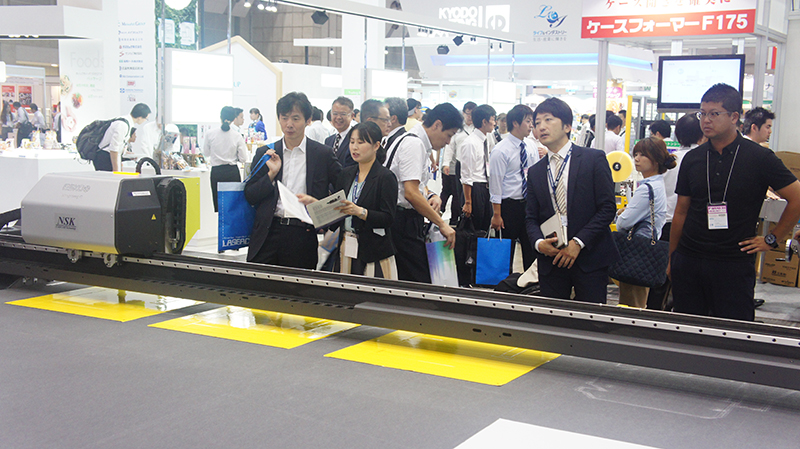

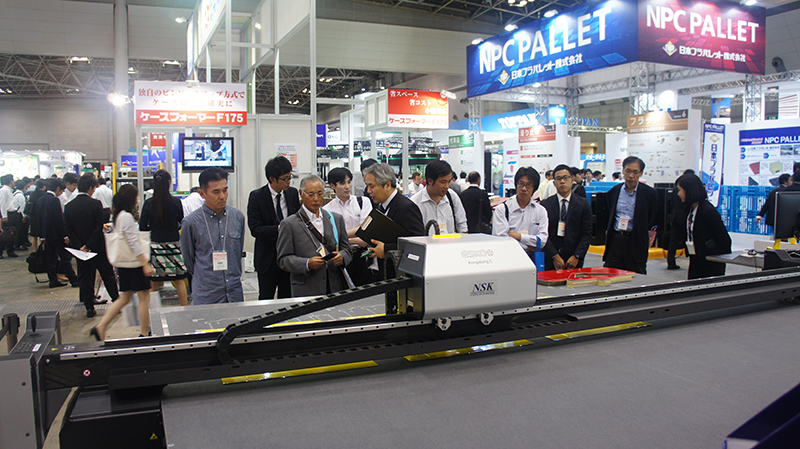

Last week, we took part in Tokyo Pack, the largest exhibition for the packing industry in Asia, which was held at Tokyo Big Sight on October 4-7, 2016.

The fair is organized every two years, and all important players in packaging machines and materials are gathered in one place. This year was no exception. New machines and state-of-the-art technologies and knowhow were displayed from all over the world, and the exhibition thrived from start to finish.

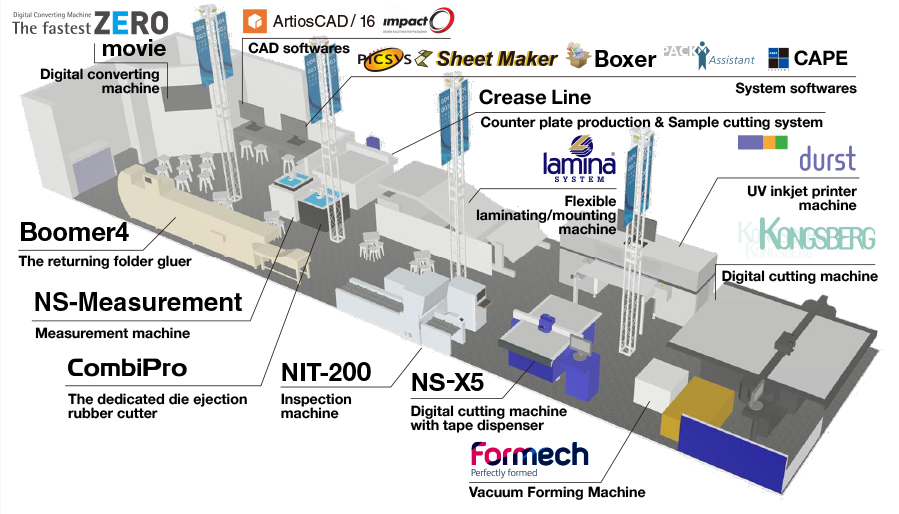

We set up a booth with "Connected Solutions" as the theme and showcased all solutions which enable improvement in many of the processes related to packaging manufacturing.

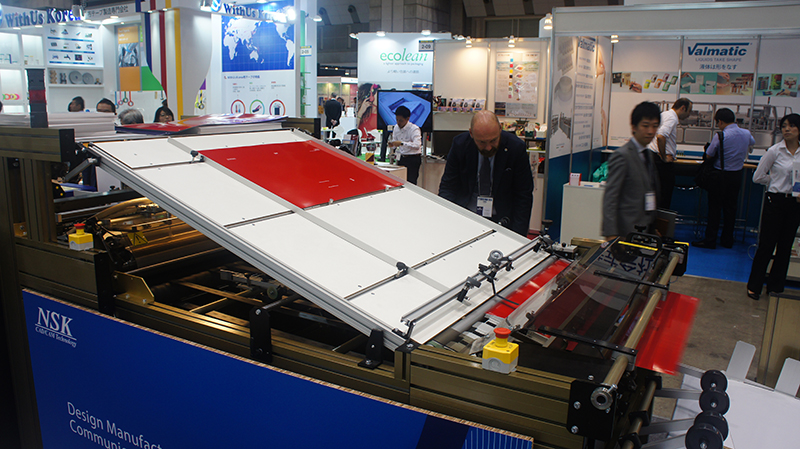

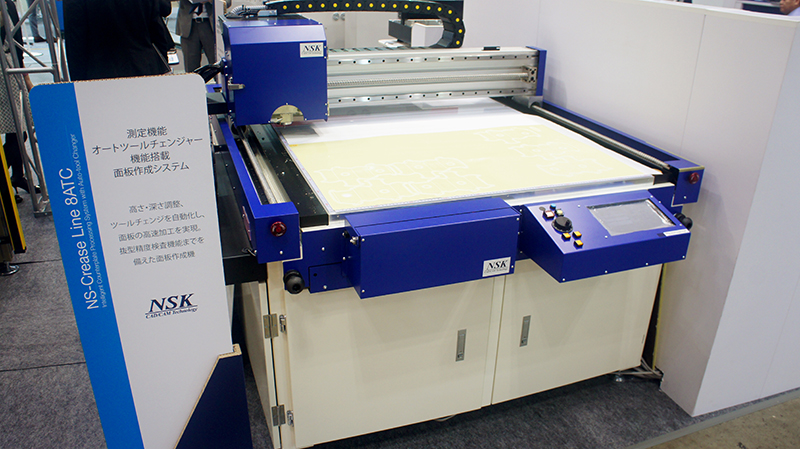

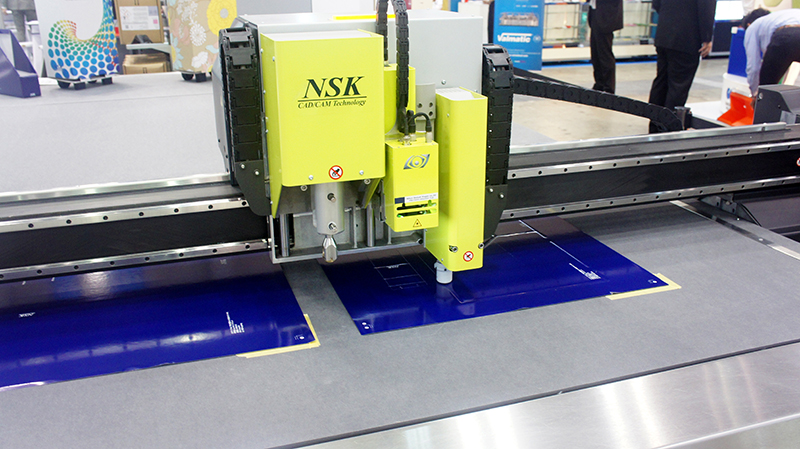

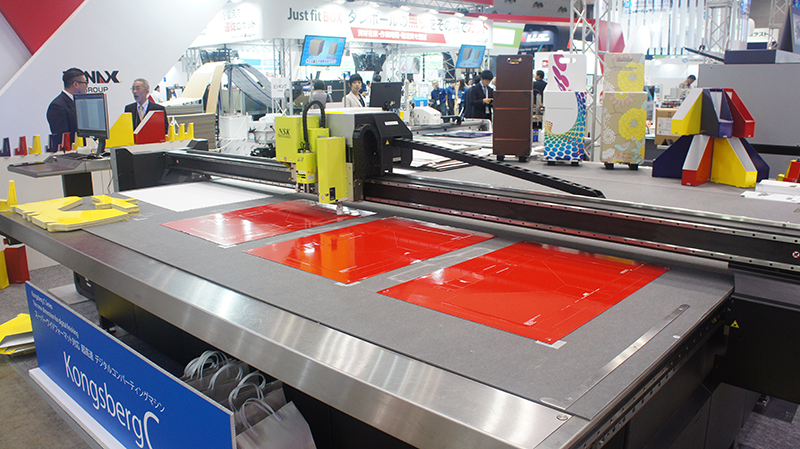

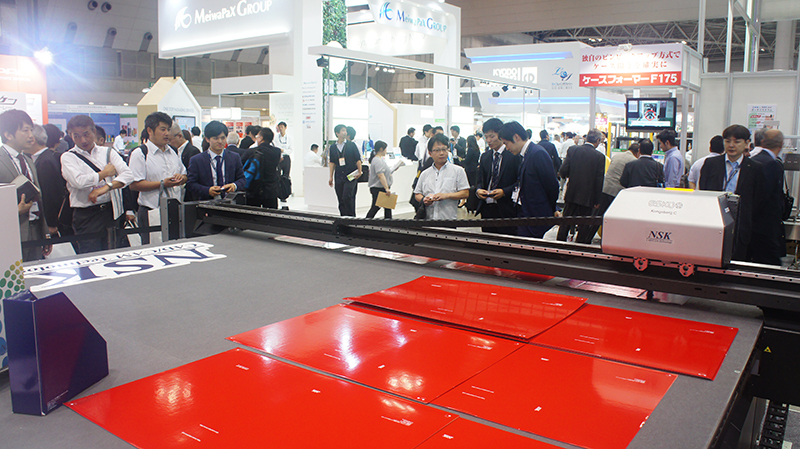

Our solutions included: High-end cutting machine Kongsberg C, with a working size of 3200 x 3200mm; Boomer4, a folder gluer with half the footprint of conventional machines; NS-X5, an entry-model cutting machine equipped with a tape-dispensing feature; and to top it all off, NIT-200, an inspection machine for smaller printed packages which allows you to check the top and bottom of a sheet simultaneously with a 200 x 300mm working size.

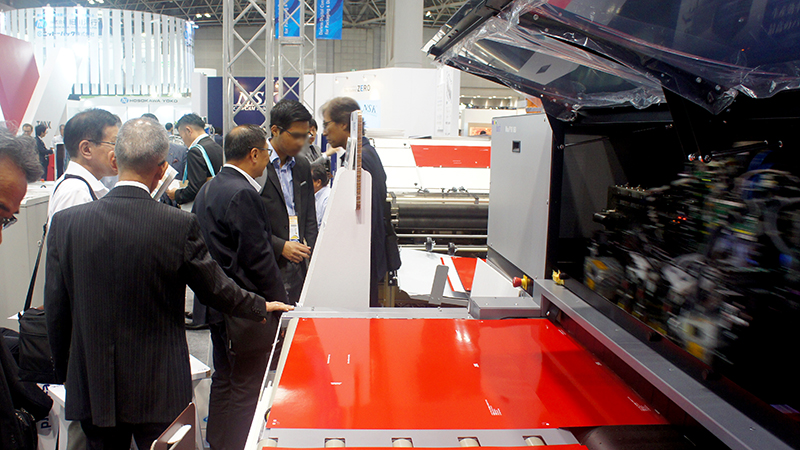

Also, we made the first announcement in Japan for Digital Converting Machine ZERO, which was also showcased at drupa 2016. The adanced concept drew a fair amount of attention from many customers.

Our solutions offered not just hardware, but also software, including ArtiosCAD 16, Management Information System PiCSYS, SheetMaker, and BOXER, a simulation software which calculates the most suitable outer box size for packing in a simple and easy way. All of these products help our customers work with integrated solutions for the packing industry, including folding cartons and corrugated.

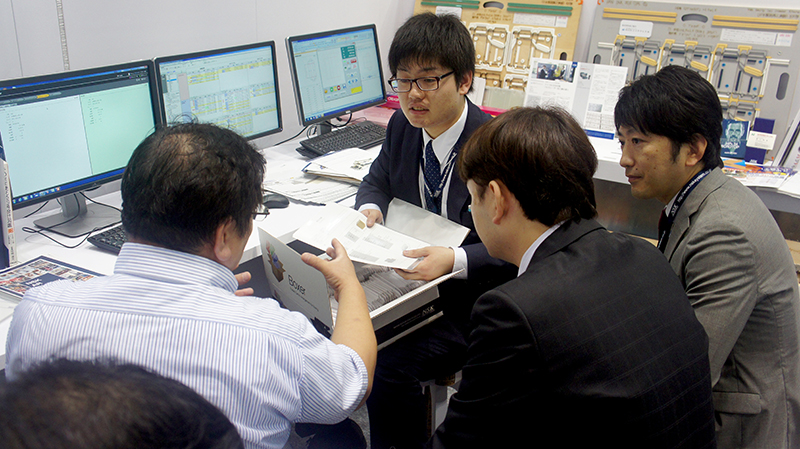

We appreciate all of the customers who stopped by our booth and took the time to see our solutions during the show.

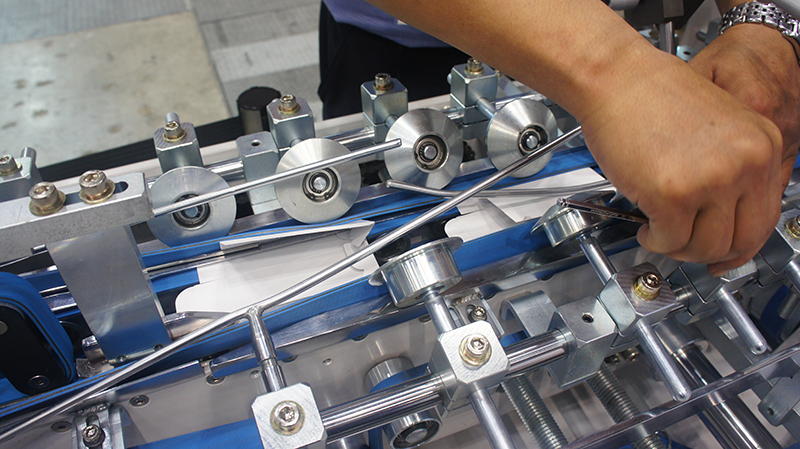

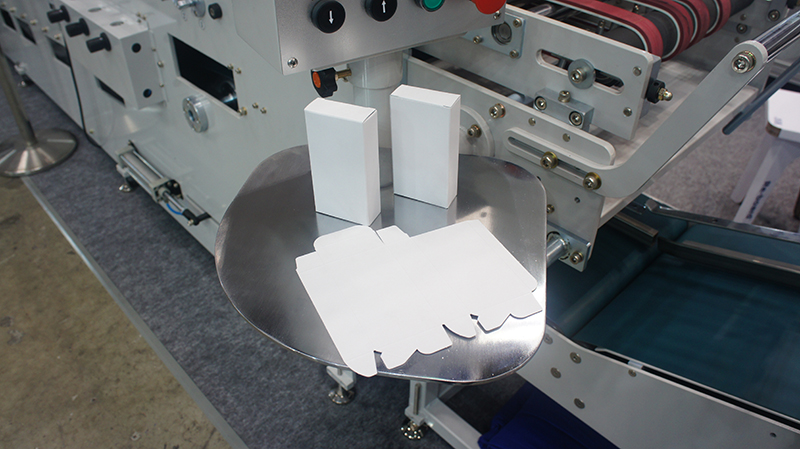

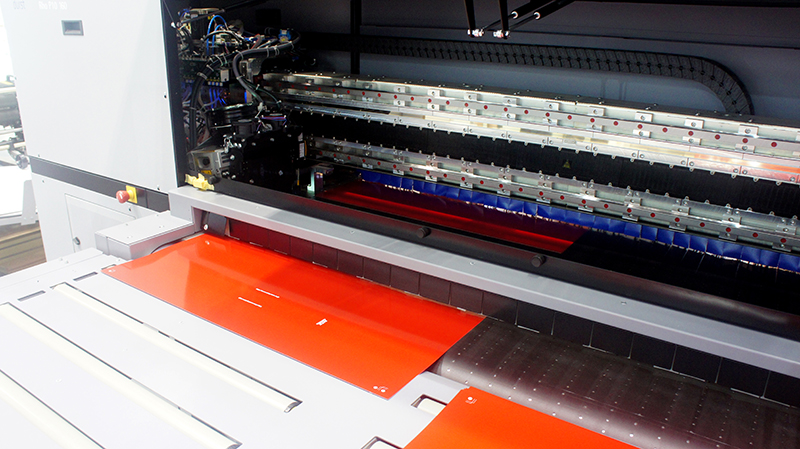

The First Showcase of NS-X5, with a New Tape Dispenser Tool Option

This new tool allows you to automate the tape application process, which is usually done manually after cutting. To set up where the tape should be applied, all you need to do is specify a line type. Of course, this can be done in horizontal, vertical, or diagonal directions, but it is even possible to specify curves if required. This is the ideal solution to increase the efficiency of your production in a quick and easy way.

TOKYO PACK 2016 Gallery

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|