Automated Digital Converting for Packaging and Display

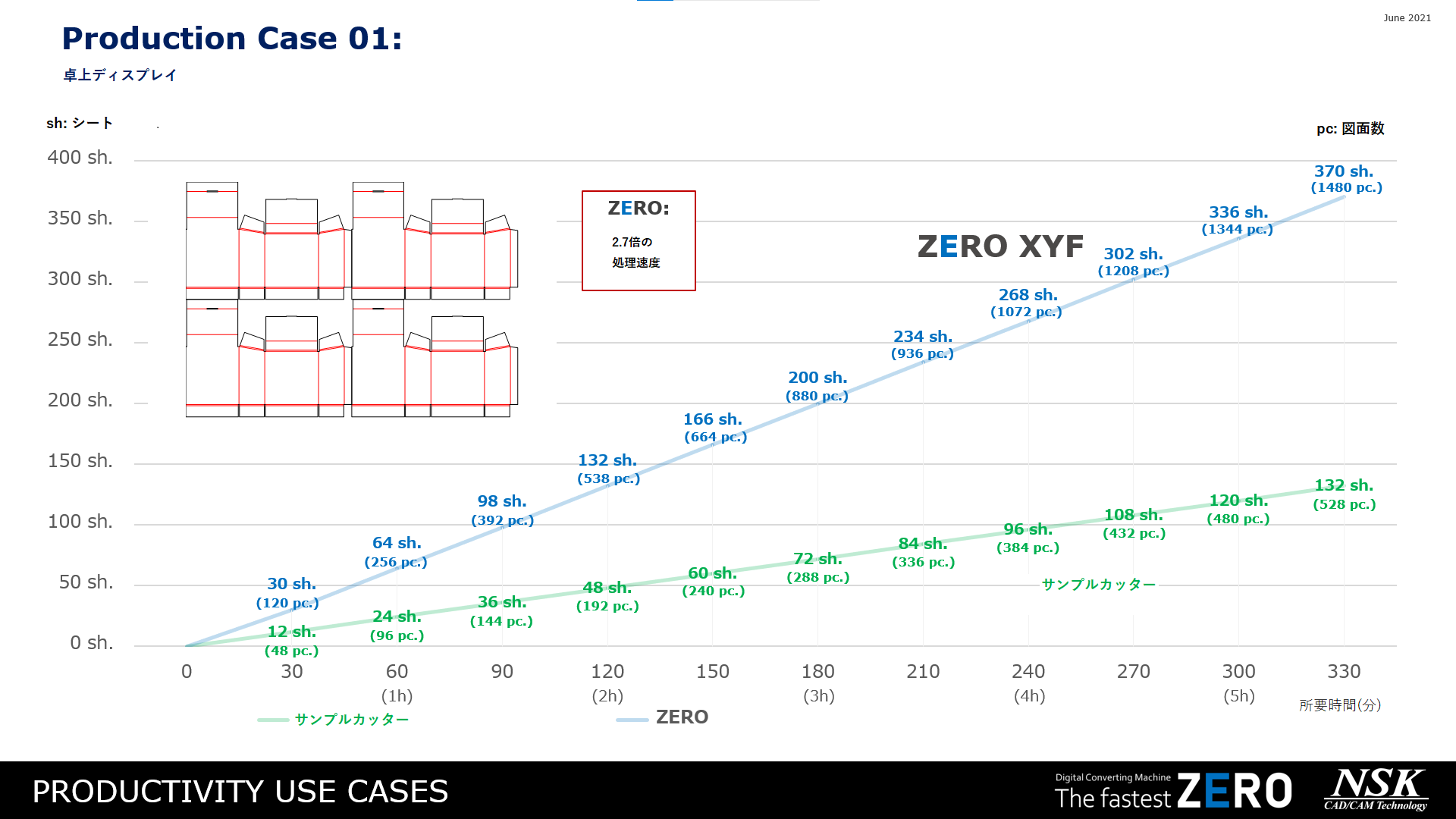

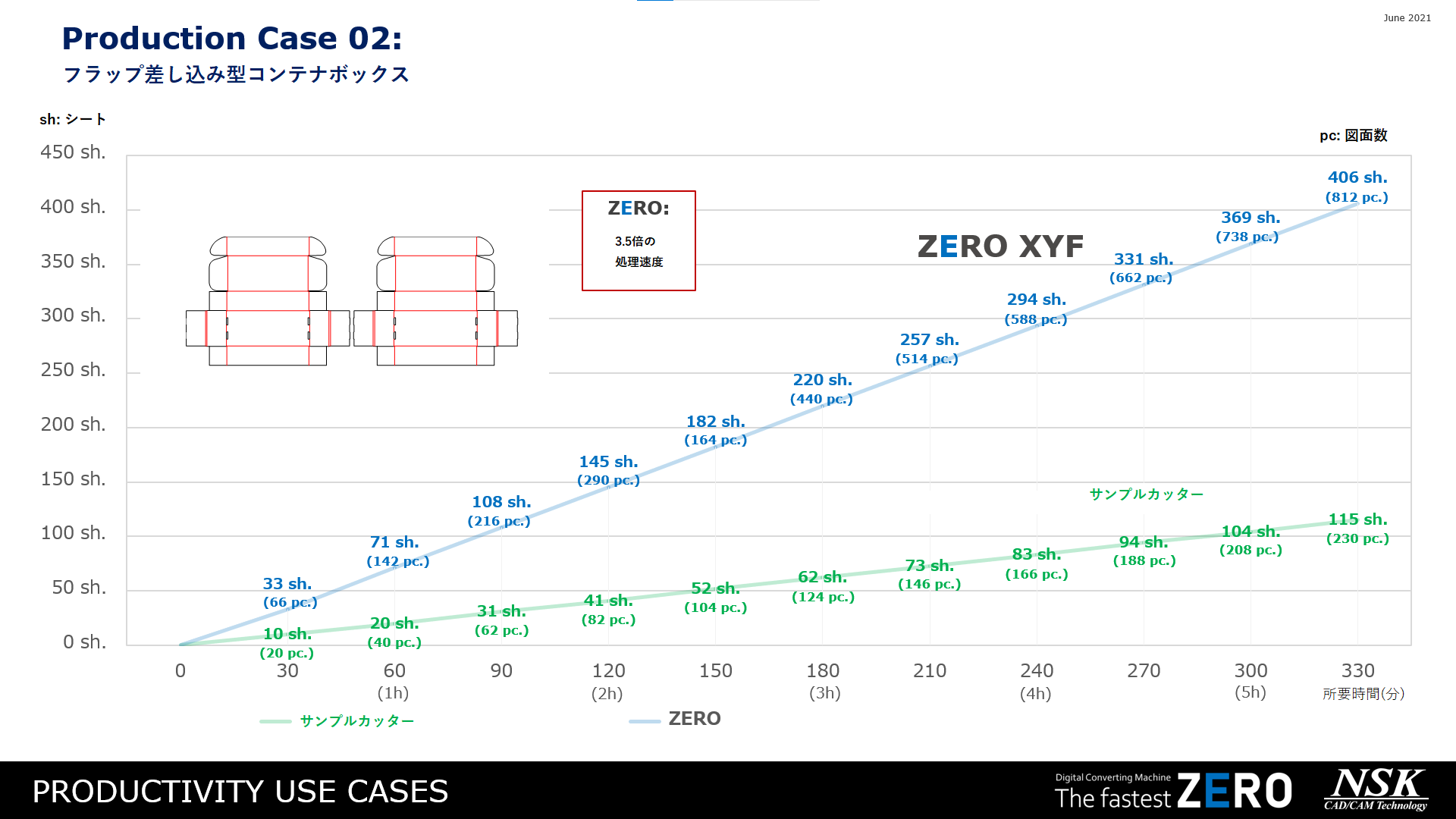

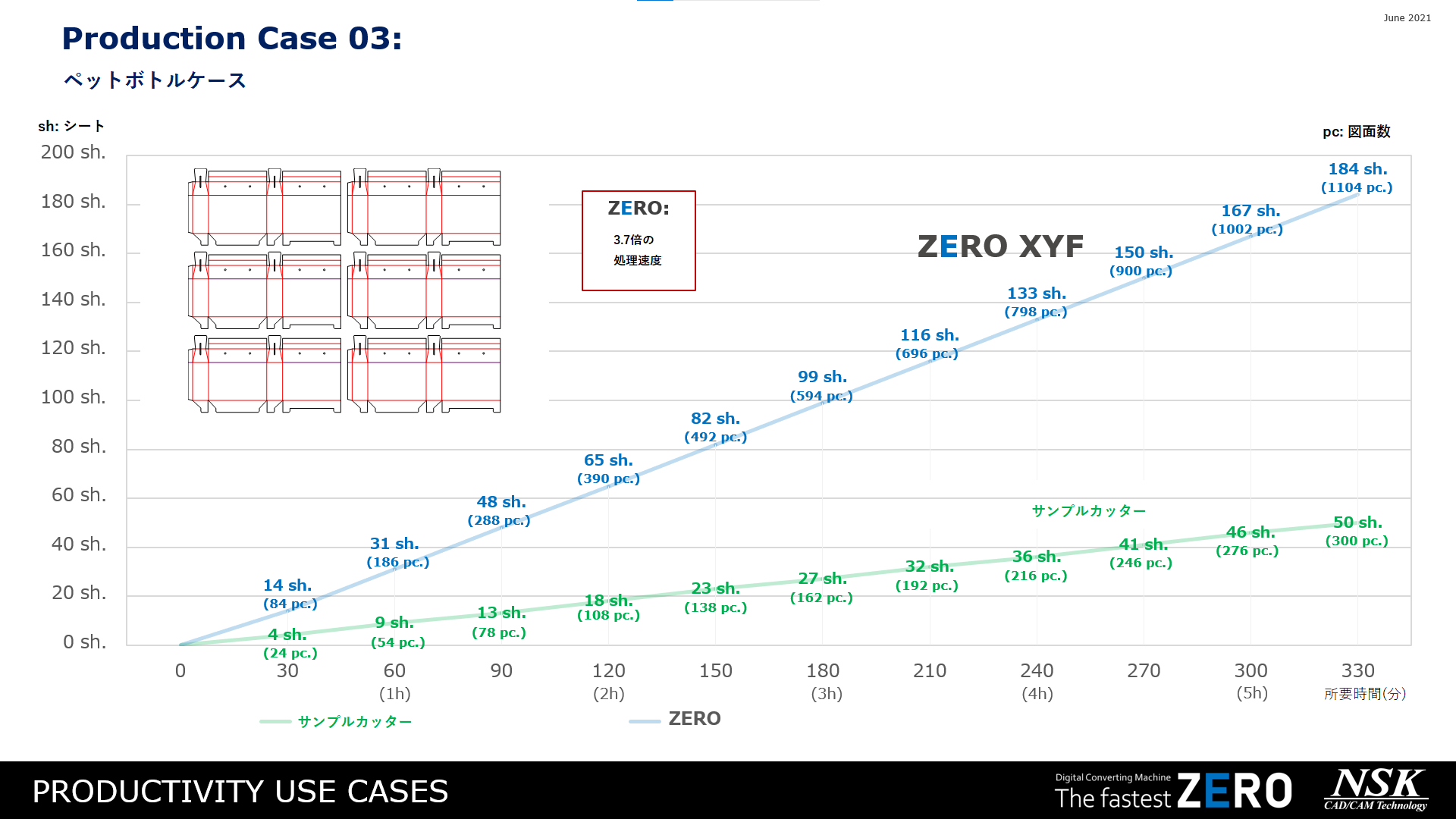

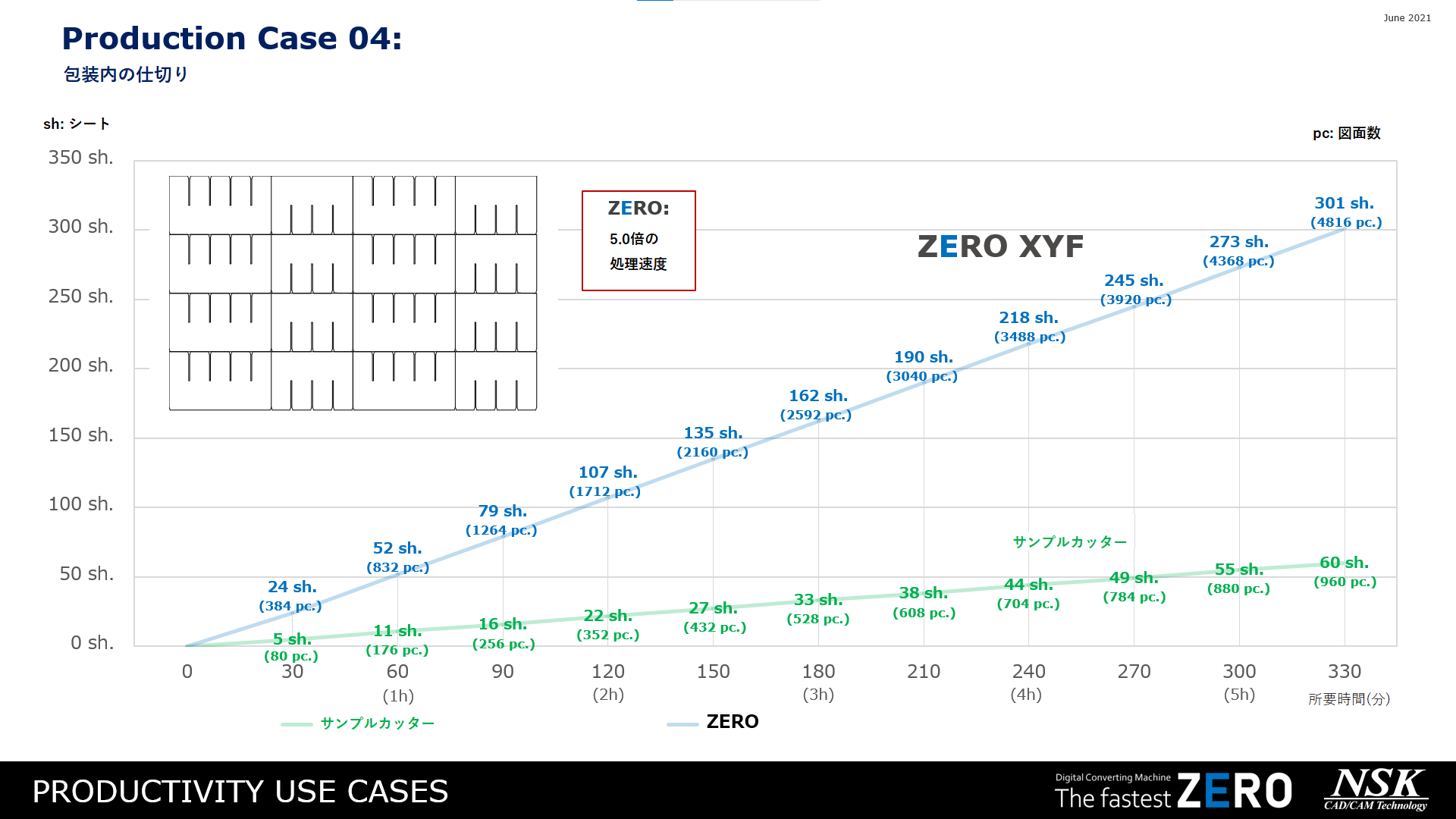

PRODUCTION CAPACITY

Fully Automatic, Digital Processing: ZERO is the Next Step.

Until recently, production has been handled by either die press machines or sample cutting tables. Die presses handle thousands of sheets per hour, while sample cutters handle up to 50 sheets per hour.

With a maximum output of 300 sheets per hour and a continued focus on improving the software, ZERO provides the fastest all-digital production in the market today.

The HARDWARE

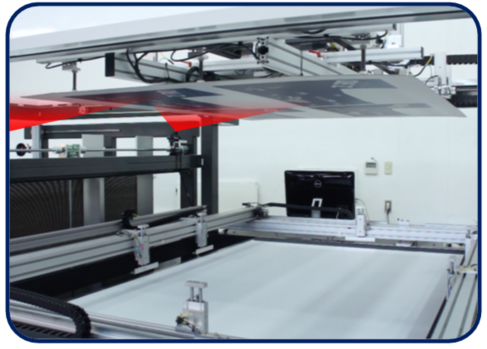

ZERO's innovative concept was designed for the automated future of processing. With faster production, built-in automation, and ease of use, ZERO is in a class of its own. Just set up the materials and press start. ZERO does everything automatically.

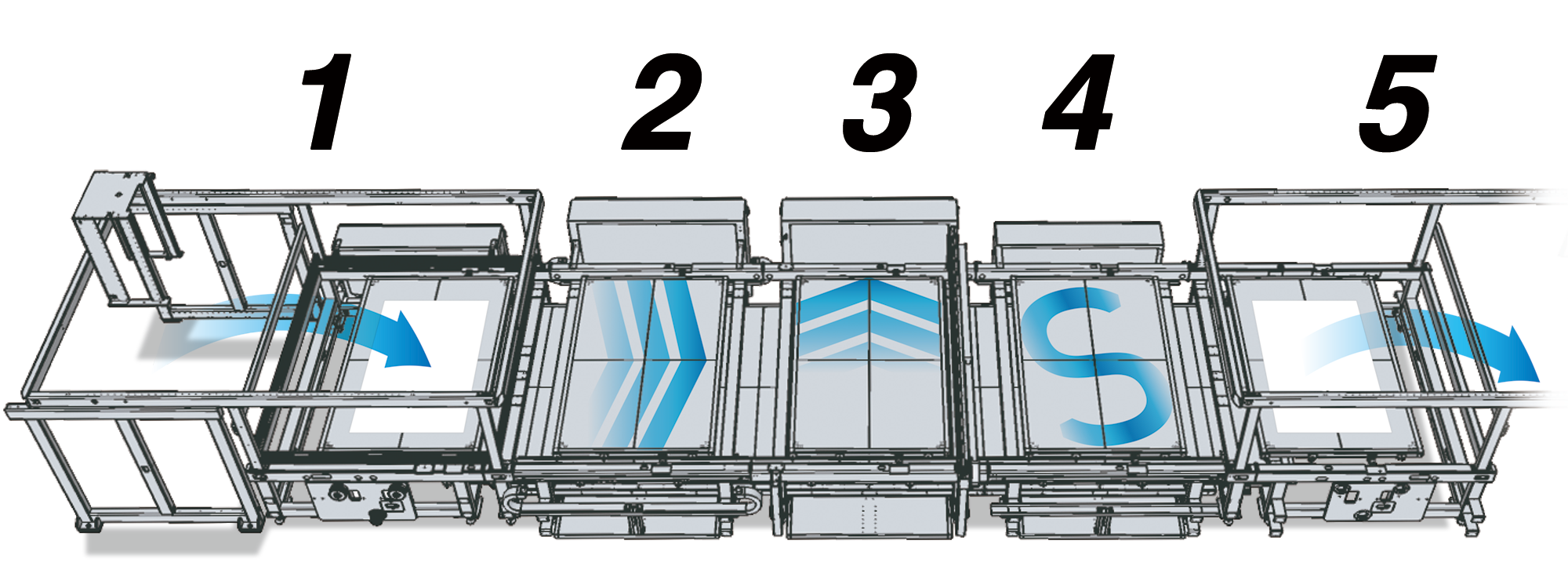

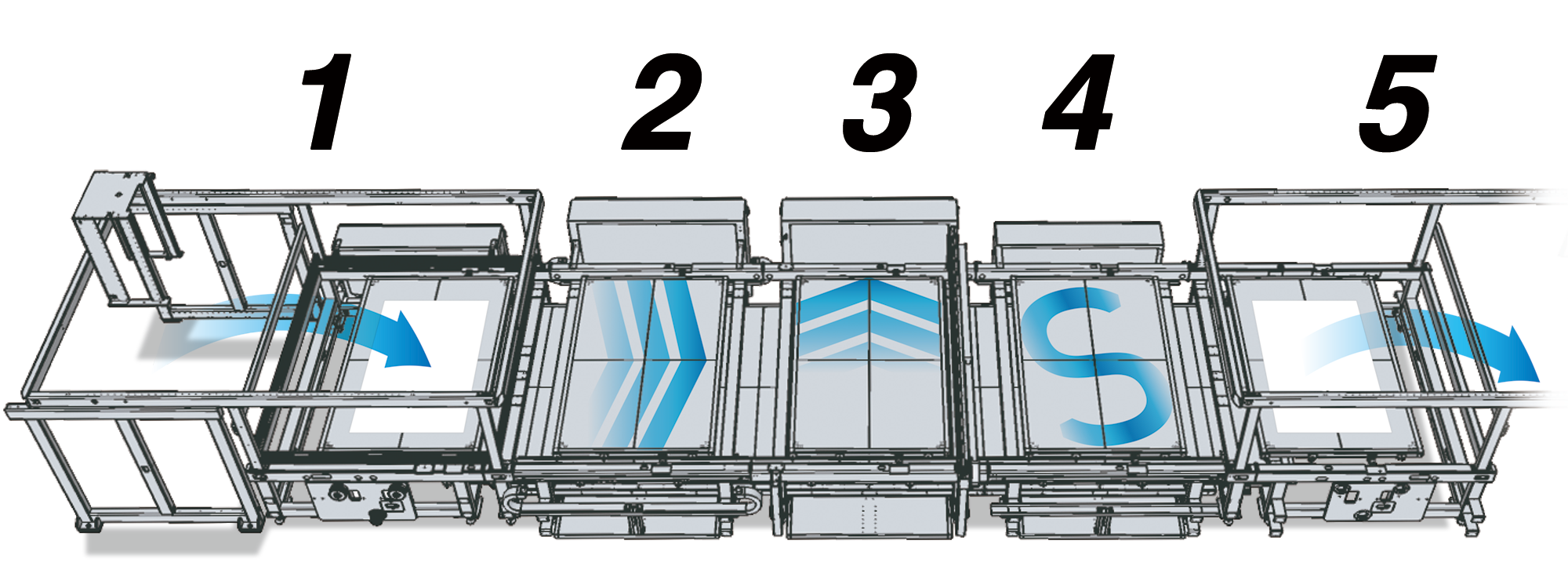

LOADING UNIT

When a job starts, the Loading Unit's pickup arm transports boards into the machine. The camera system checks the alignment of each sheet and adjusts for placement.

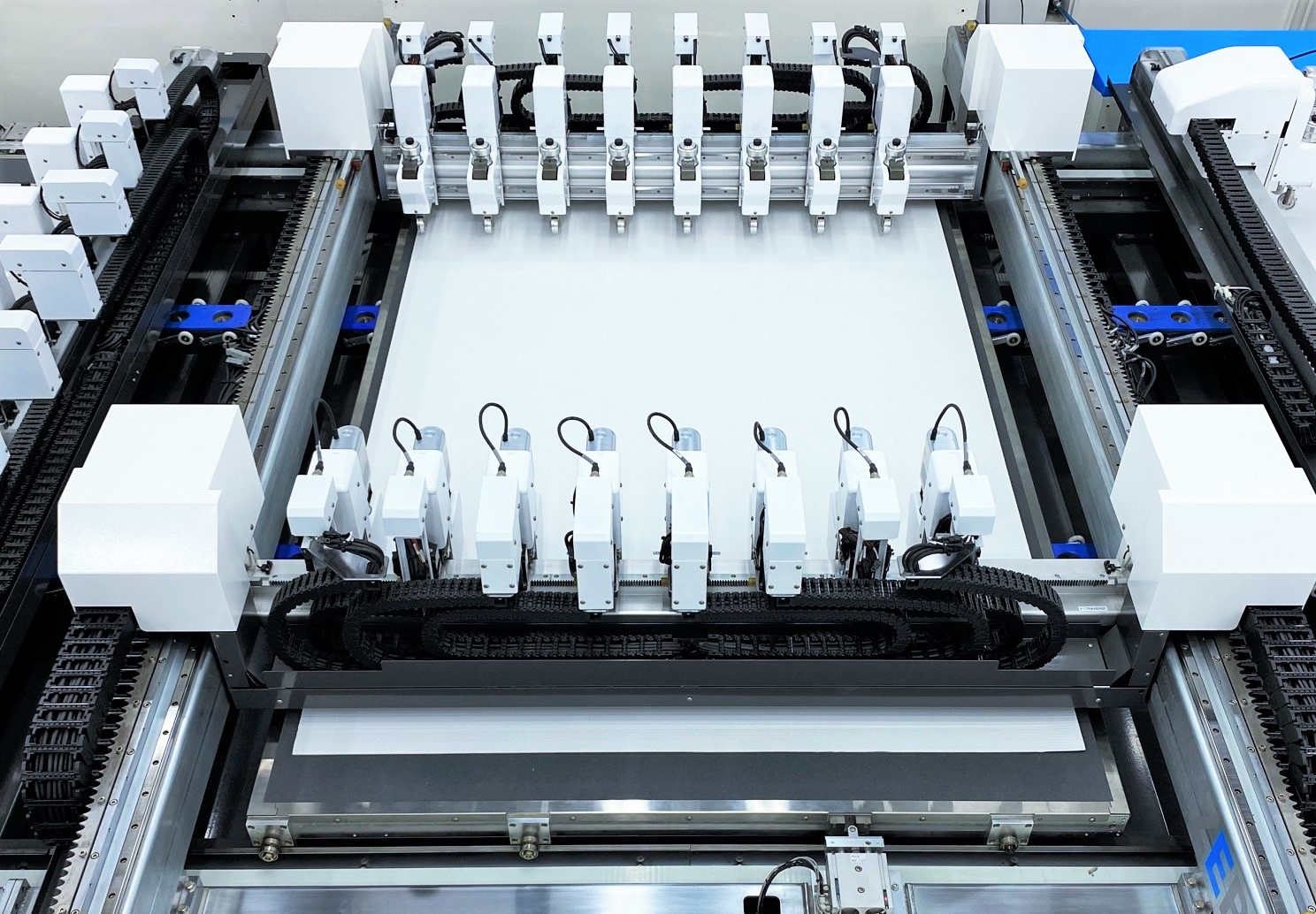

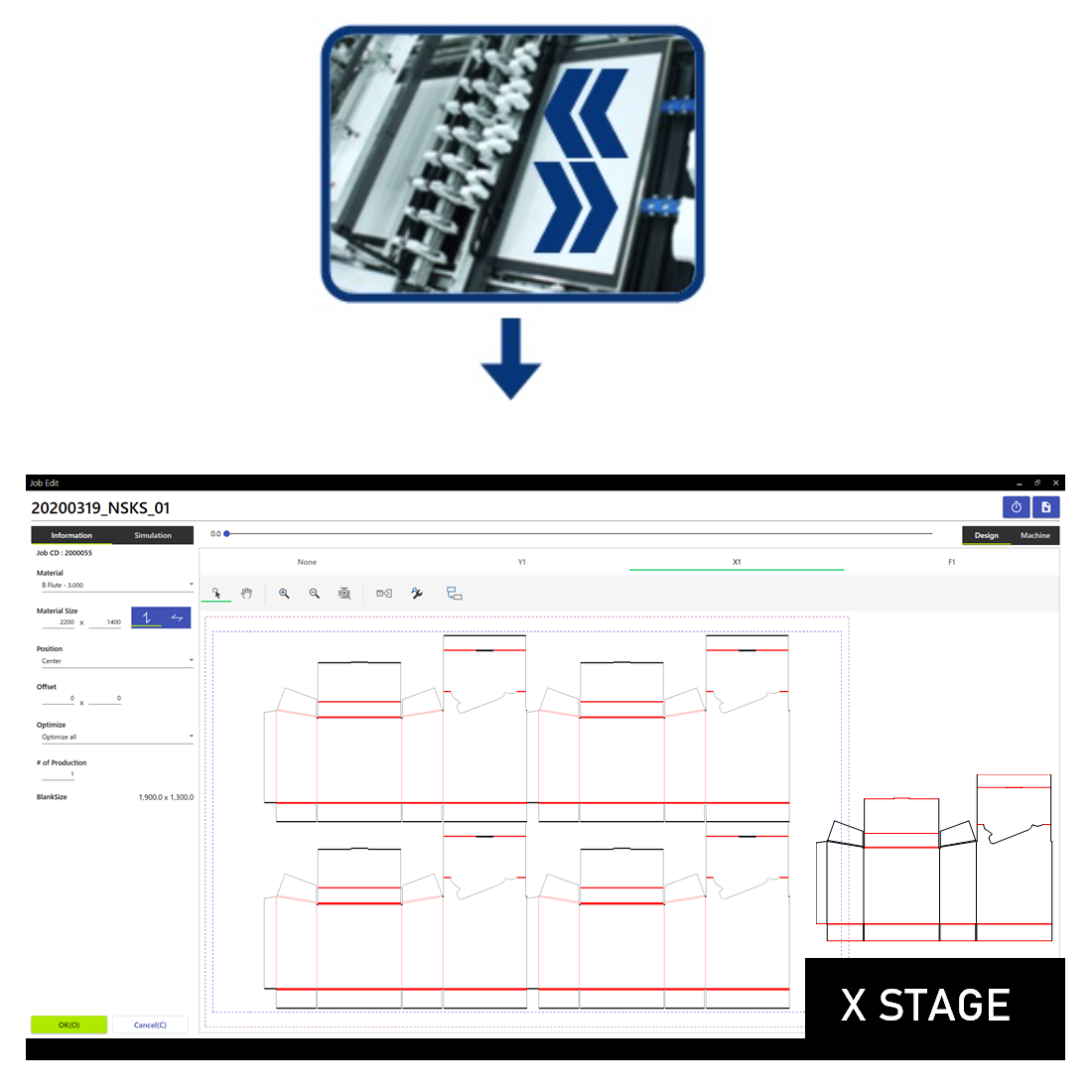

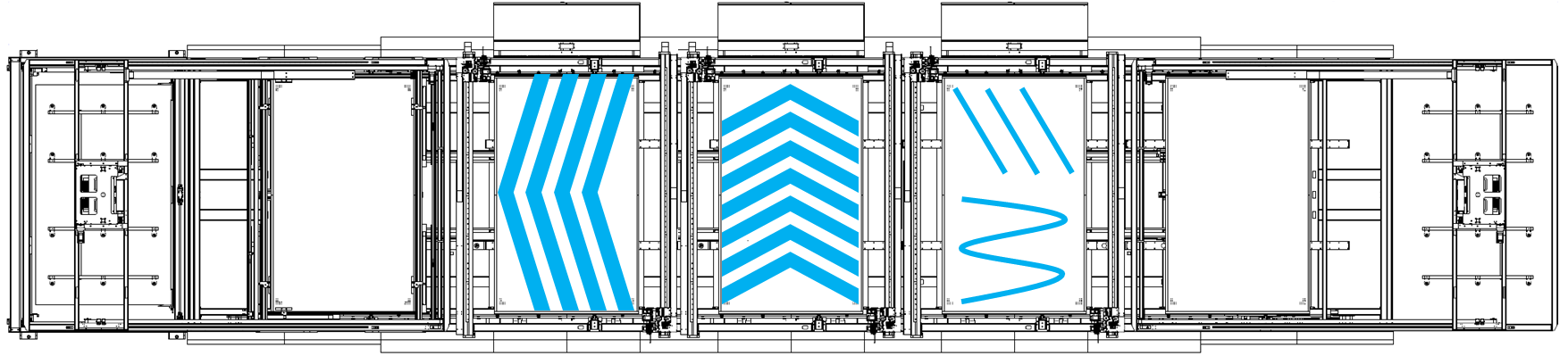

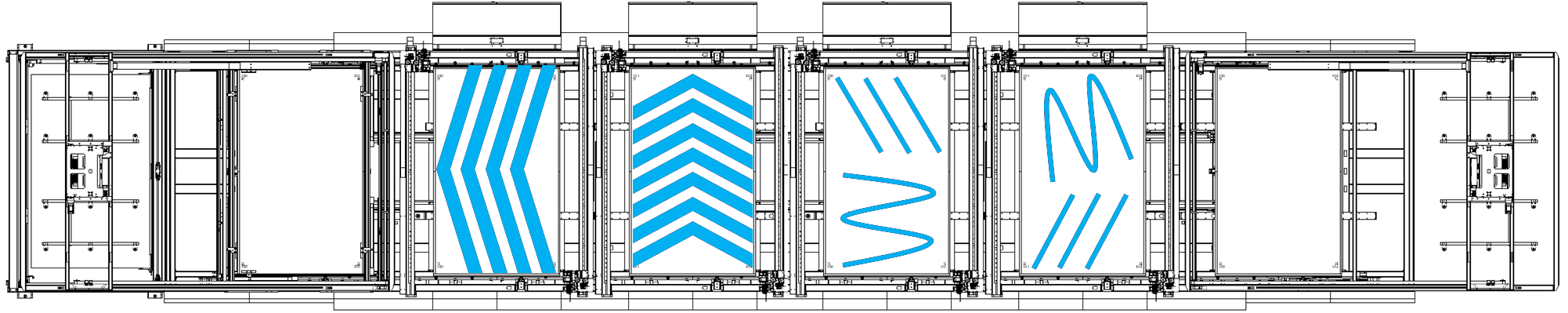

X STAGE

Horizontal cut and crease data is processed by up to 16 individual tools. All lines are processed at the same time to achieve faster production.

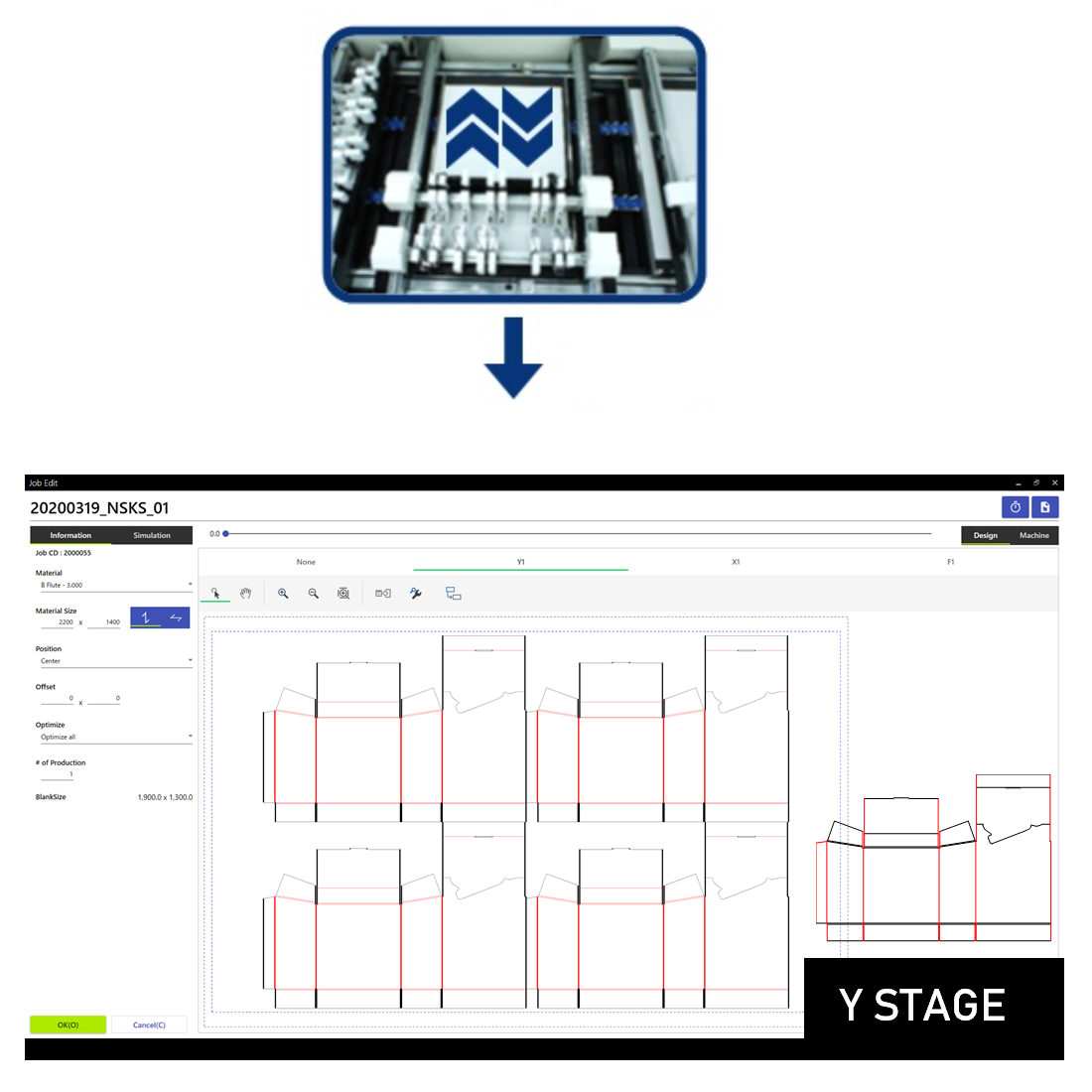

Y STAGE

Vertical line data is processed according to the data file. The tools move up and down across the table with high speed and precision.

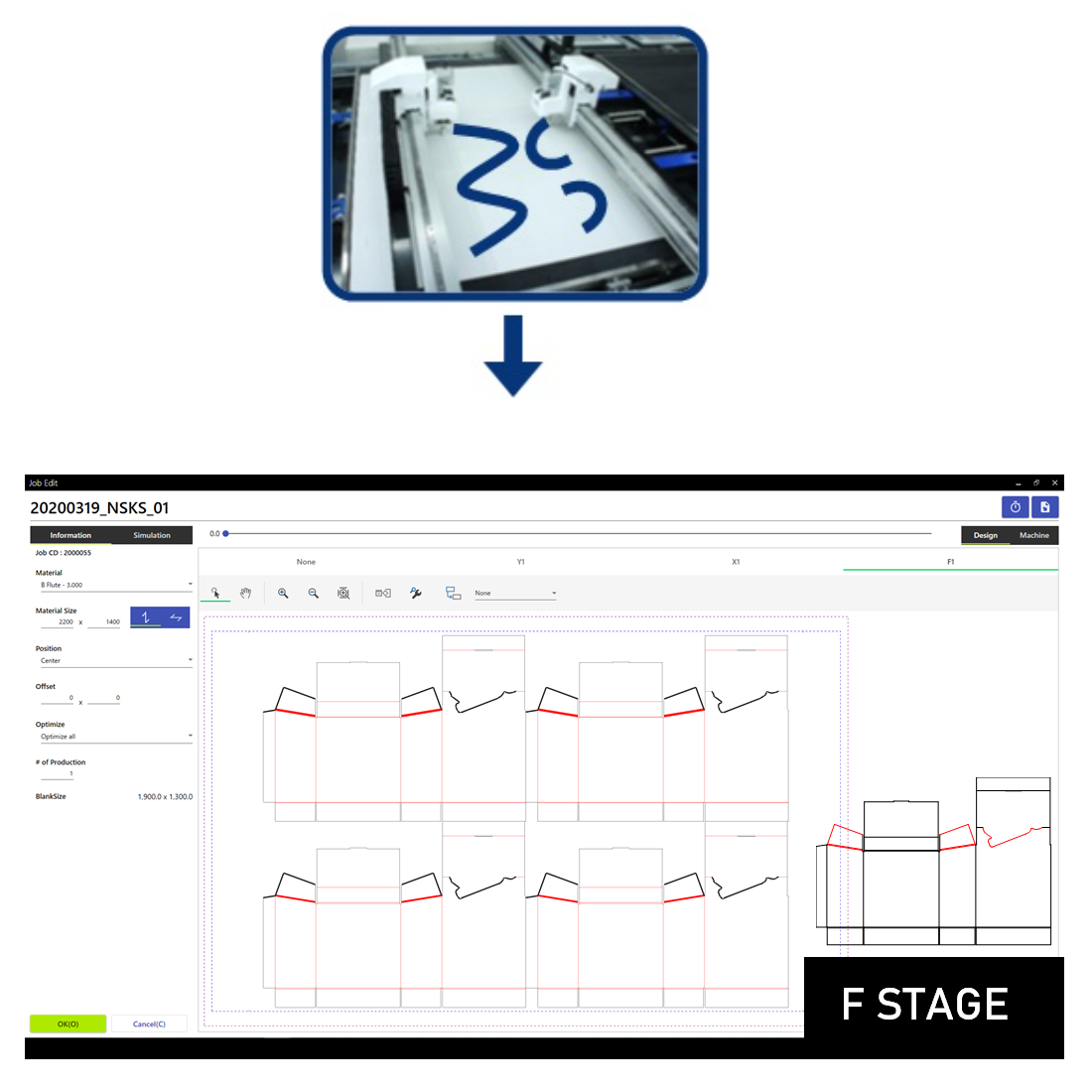

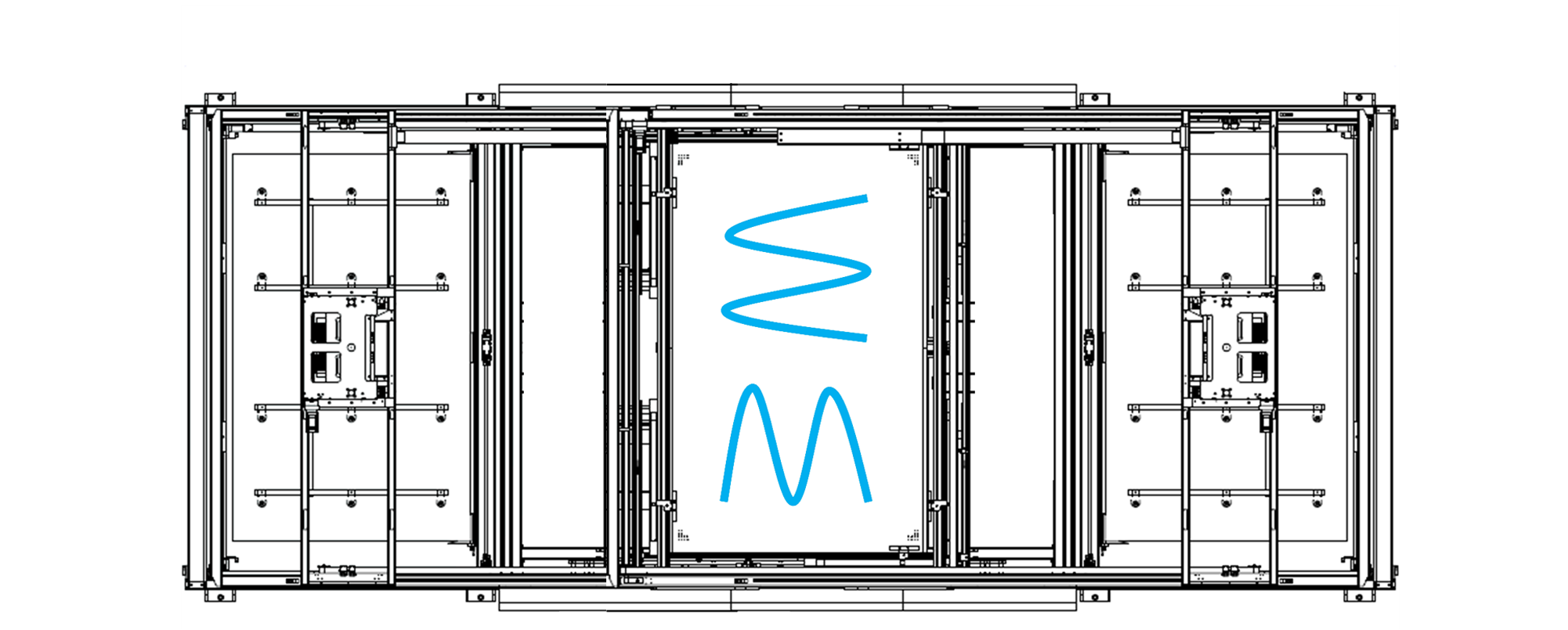

FREE STAGE

All remaining line data is processed on the free stage. Dual twin heads cut and crease diagonal and curved lines for greater productivity.

UNLOAD UNIT

The Unloader Arm takes finished sheets and stacks them for easy removal. The Unloader's vacuum panel ensures that no pieces are left behind.

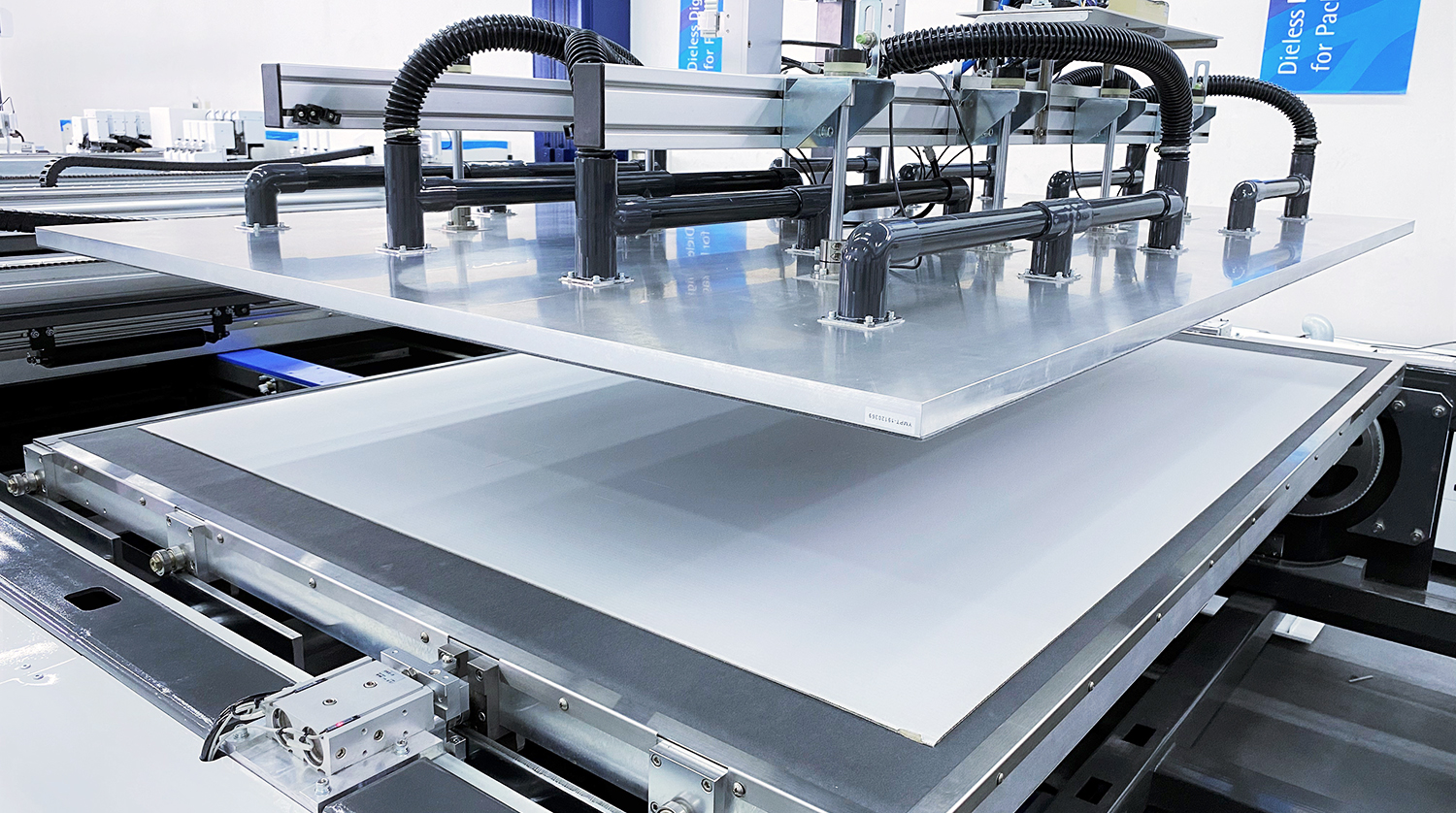

SHUTTLE TABLES

Materials are held in place by vacuum and move through the machine on revolving shuttle tables. The tables lock into place at each stage before processing begins.

The SOFTWARE

Simple, Intuitive Operation. Get Started Faster.

Import a file, enter the job settings, and press start.

ZERO handles the processing automatically.

Import, Edit, and Review

Import a file and ZeroCC automatically separates the processing lines into X, Y, and Free Stages.

Each Stage can be viewed separately to review how the job will be processed. Material settings, job size, and more can be selected during Job Editing.

X STAGE

Y STAGE

FREE STAGE

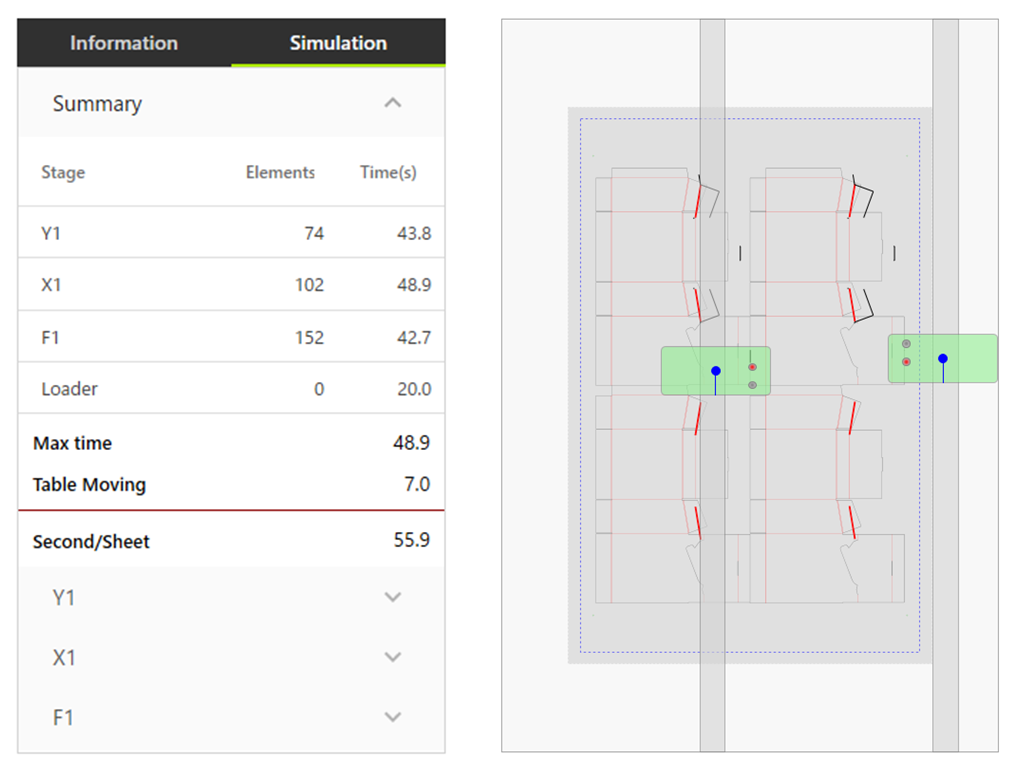

Stage Changing and Production Simulator

Depending on the data, productivity can be increased by moving cut and crease lines to other compatible stages. If one stage takes too long, moving lines can reduce the processing time for even more efficient job completion.

The ZeroCC has a built-in simulator to calculate each stage’s production time. The Stage Change and Simulator functions work together to maximize productivity of the ZERO Machine.

The Tools

ZERO has a wide range of tools available to meet today's industry needs.

Use the right tools to expand your Packaging and POS/POP capabilities.

Knife Cutting

ZERO has a wide variety of knife tools to ensure clean, consistent cuts on the most commonly used industry materials.

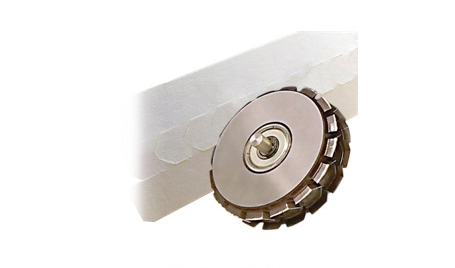

Creasing

ZERO's single-ruled and double-ruled creasing tools in several widths provide several choices for crease production and speed.

NSK's knowledge and industry experience brings unique solutions to ZERO. Enhance your factory capabilities with one-of-a-kind tooling options.

Tape Application

ZERO

is the only display processing solution with an option for inline,

CAD-based application of either double-sided tape or magnetic tape.

Perforation

In

addition to conventional perforation tools, NSK's original Zipper Tool

makes easy-to-open packaging production simple as a straight line.

Tools are continually in development for use with ZERO. Please contact us to discuss your specific tool needs.

Additional Options

ZERO is a versatile system with many additional options that provide users a solution tailored to their needs.

Heads and Tools

Select the number of heads for each stage, and choose from a variety of processing tools.

Up to 16 tools on the X and Y Stages, and up to 6 tools on the F Stages can be added for faster cutting, creasing, and even more specialized applications.

Tool Inspection

The Tools Inspection system uses a camera to check knife tool cutting to make sure the sheets are being cut properly.

A separate option includes a sensor at each stage which checks at user-set intervals, minimizing losses from damaged knives.

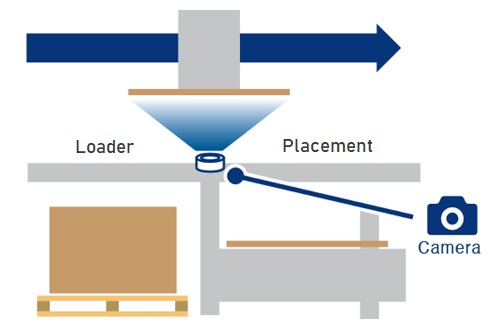

ZERO Camera Alignment

The ZERO Camera option reads printed boards from underneath, making cutting and creasing an operator-free process.

The camera reads all marks and checks the sheet alignment, which is then adjusted by the Loading Unit for placement accuracy.

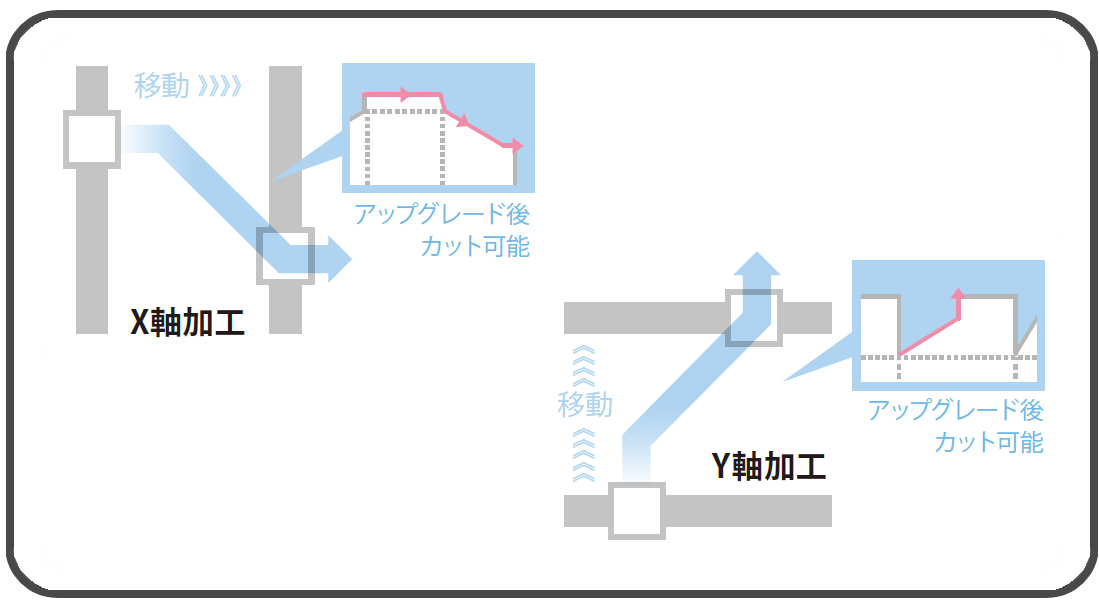

Future Upgrades

The ZERO team is dedicated to making improvements to ZERO's software through a continued focus on optimization, updates, and development of new features.

A future software upgrade will allow ZERO's X and Y stages to cut diagonal lines, expanding the compatible line handling for each stage to provide dramatic improvement to ZERO's processing speed.

This performance feature upgrade will be included free only for a limited time with ZERO orders now.

COMPATIBLE MATERIALS

The CONFIGURATIONS

Stage Configurations

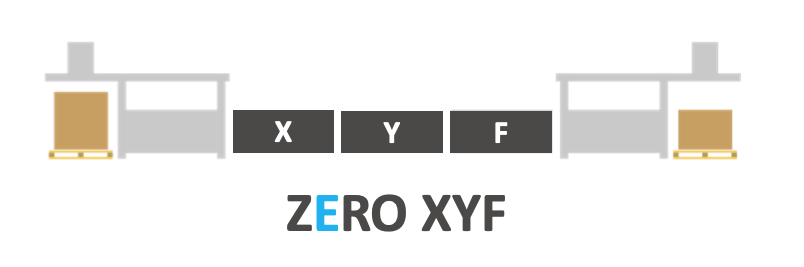

ZERO XYF and ZERO XYFF provide production level speed according to the ZERO concept.

ZERO XYFF has an additional Free Stage for faster processing of diagonal lines and arcs.

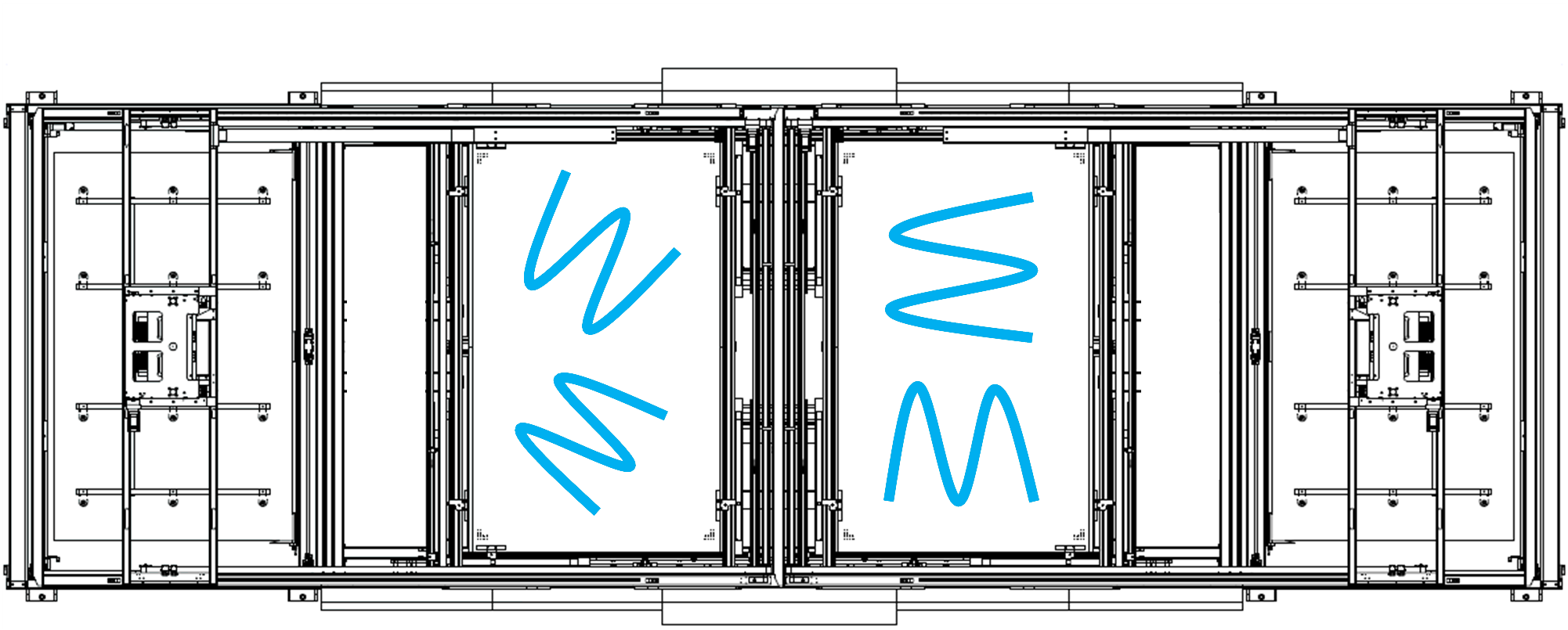

ZERO F and ZERO FF provide

side-by-side production on static tables, which combines conventional

cutting table speed with ZERO's powerful automation features.

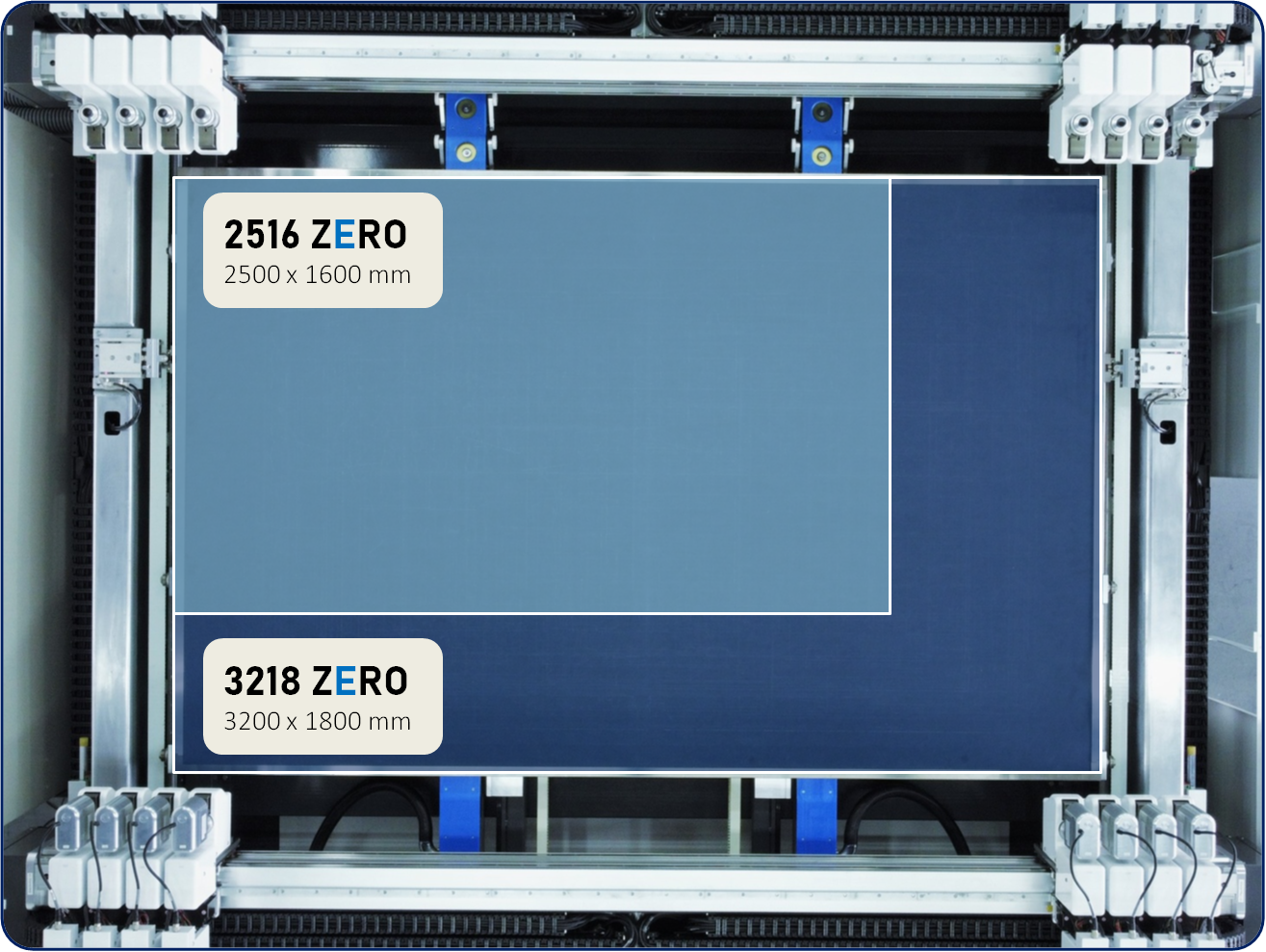

The ZERO system has been designed with two sizes in mind for handling the greatest variety in processing, based on the most popular standard printing widths.

ZERO 2516 | ZERO 3218 | |

|---|---|---|

Work Area | 2500 x 1600 mm | 3200 x 1800 mm |

X Stage | 10 Tools | 12 Tools |

Y Stage | 8 Tools | 10 Tools |

Place your pallet in the Loader zone with the printed side down. The camera system reads the board from underneath as the pickup arm passes over.

Once the marks have been read, the stacker unit shifts and rotates to place each board properly on ZERO's shuttle tables.

The SPECIFICATIONS

XYF 2516 | XYF 3218 | |

|---|---|---|

Work Area | 2500 x 1600 mm | 3200 x 1800 mm |

X Stage | 10 Tools | 12 Tools |

Y Stage | 8 Tools | 10 Tools |

Free Stage | 2 Twin Heads | 2 Twin Heads |

XYFF 2516 |

XYFF 3218 | |

|---|---|---|

Work Area | 2500 x 1600 mm | 3200 x 1800 mm |

X Stage | 10 Tools | 12 Tools |

Y Stage | 8 Tools | 10 Tools |

Free Stage 1 | 2 Twin Heads | 2 Twin Heads |

Free Stage 2 | 2 Twin Heads | 2 Twin Heads |

F 2516 | F 3218 | |

|---|---|---|

Work Area | 2500 x 1600 mm | 3200 x 1800 mm |

Free Stage | 2 Twin Heads | 2 Twin Heads |

FF 2516 | FF 3218 | |

|---|---|---|

Work Area | 2500 x 1600 mm | 3200 x 1800 mm |

Free Stage 1 | 2 Twin Heads | 2 Twin Heads |

Free Stage 2 | 2 Twin Heads | 2 Twin Heads |